Our Print Methods

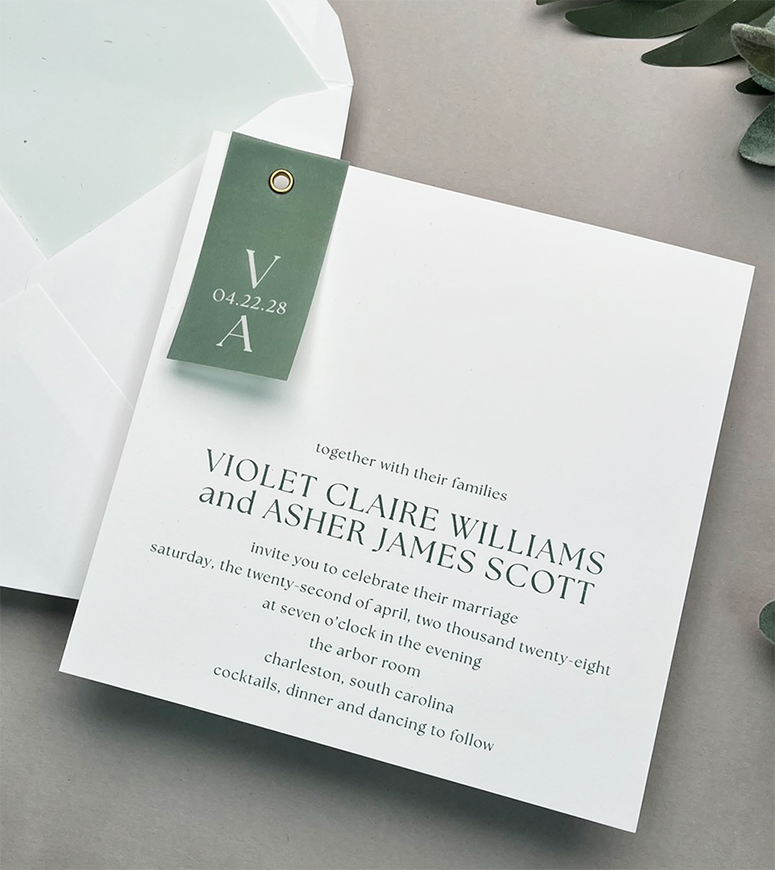

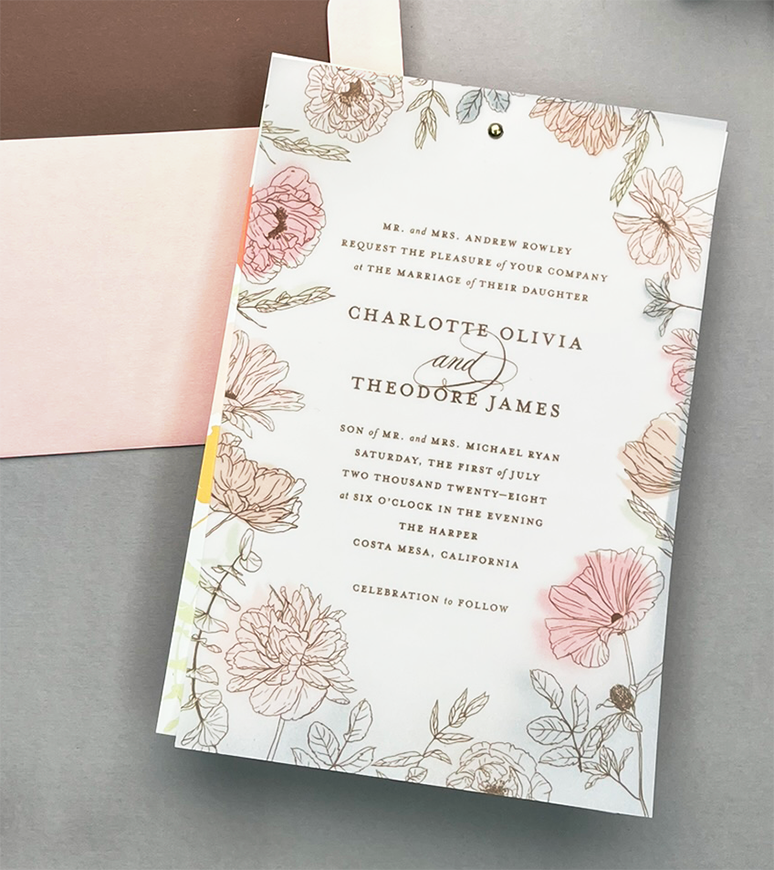

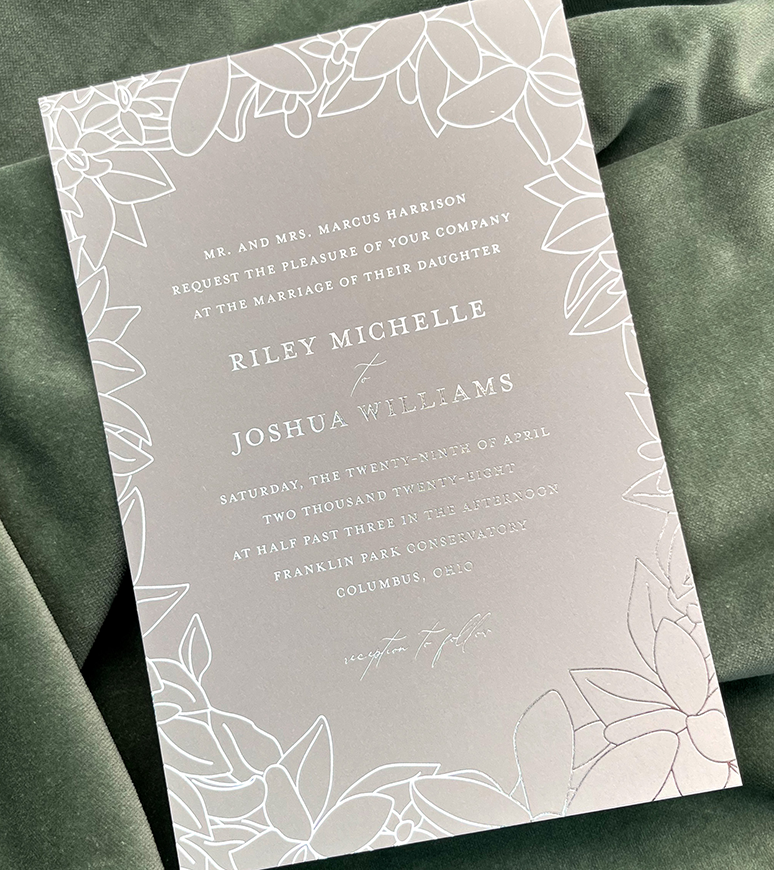

Digital

The newest, most versatile print method on the block! Digital images are transferred to a canvas in one pass, using lasers, charges and ink. The printed finish is smooth (similar to flat offset printing) but no plate is needed and an almost unlimited number of colors is able to be printed at once. This means an image can be transferred to paper more quickly and efficiently than with a plate-based process. Skilled operators prepare digital files for print and utilize computer processes to print the images. Constant attention is paid to color, coverage, paper feeding, and press callibrations to assure consistent, high quality prints throughout each and every print job. They can even incorporate variable printing like guest names on place cards or guest addressing on envelopes.

Digital printing is often followed by a UV coating to create a protective, rub resistant layer. The UV coating maintains the beautiful matte finish of the ink.

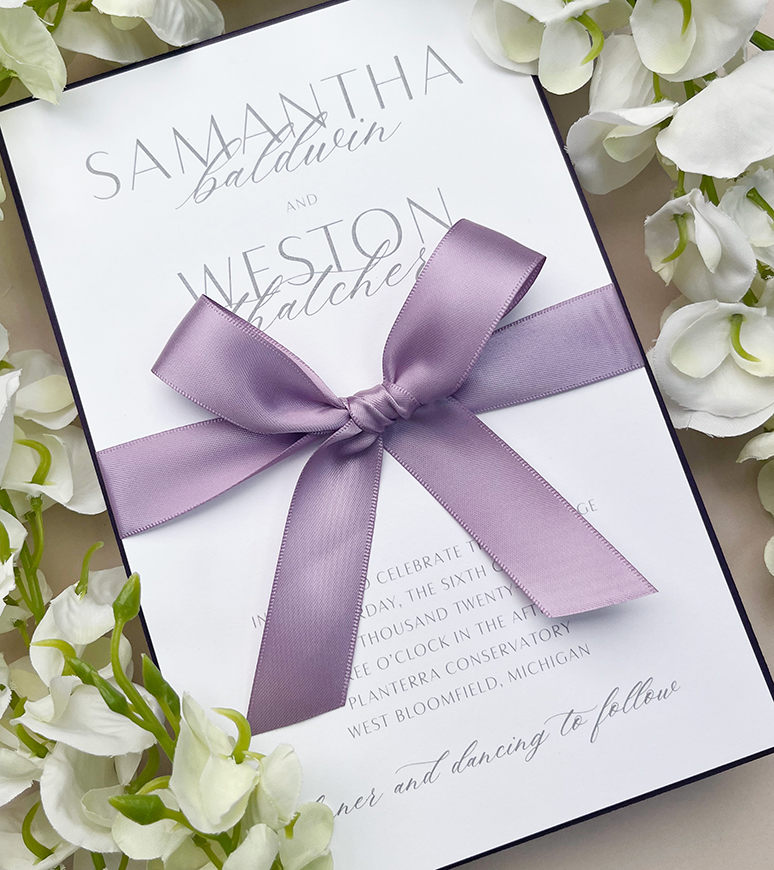

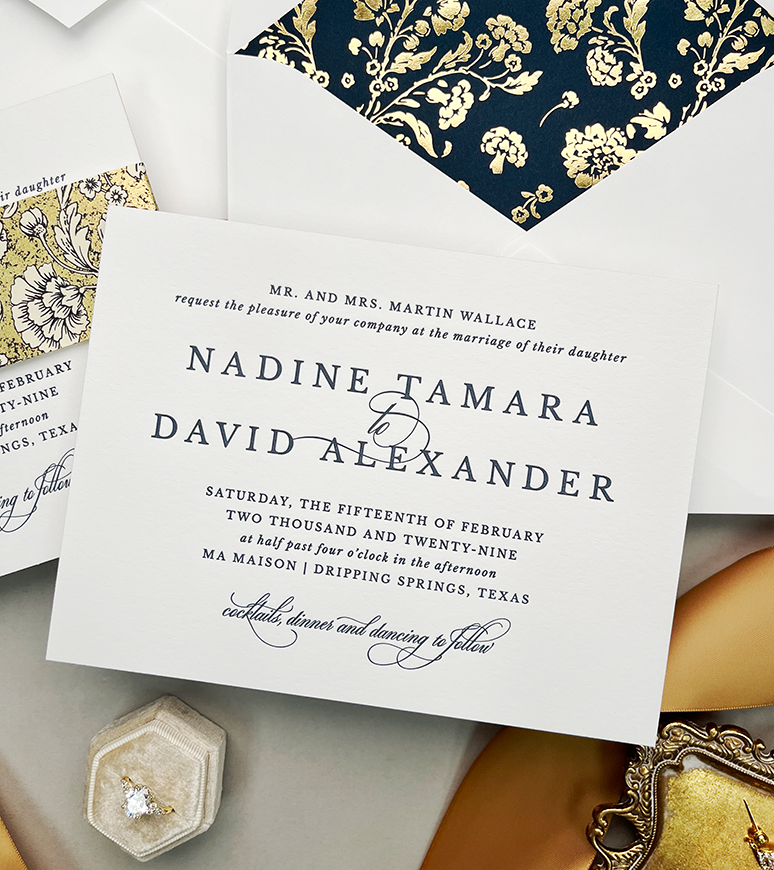

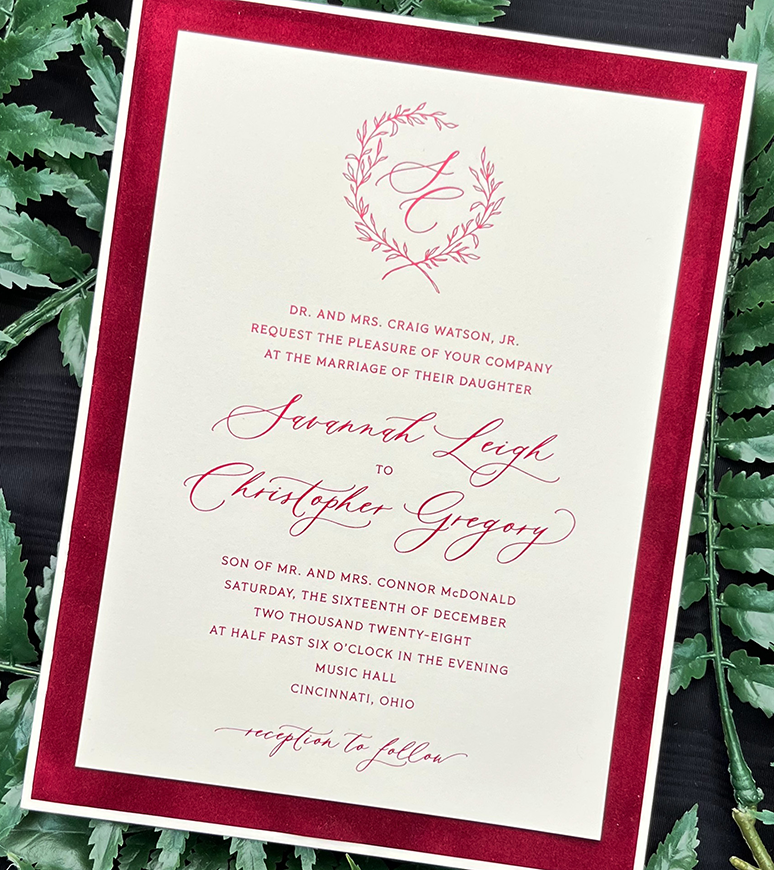

Thermography

Thermography is a print method that is built upon flat offset printing, one of the most common flat printing methods, to create printed pieces with an exquisite raised effect. While offset printing and thermography are more modern in the world of printing, press operators need a balance of artistry and mechanical expertise–nothing computerized here! The operators diligently tend to the presses–applying one ink color at a time, aligning the plate, feeding the paper, gauging the speed and assessing the ink, and making adjustments for consistency throughout each and every print job.

To get the signature raised effect of thermography, a printed piece undergoes three additional steps. First, thermography powder is sprinkled onto the card. Some powder bonds with the wet ink while the excess is removed. Then the card is heated to melt and activate the powder which raises the ink. The result is a beautiful and wonderfully tactile work of art!

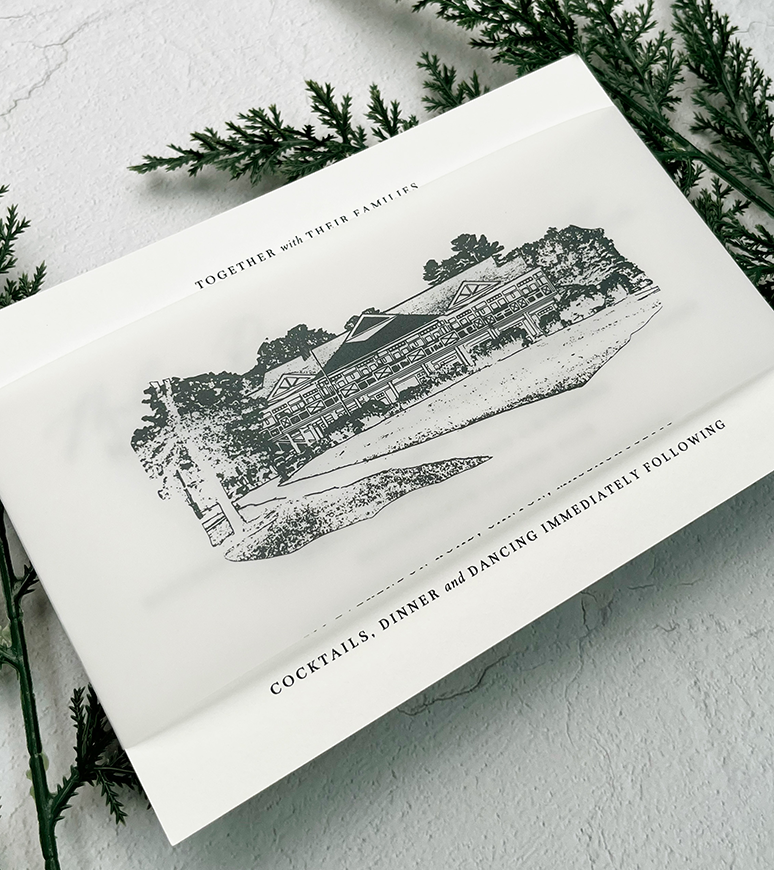

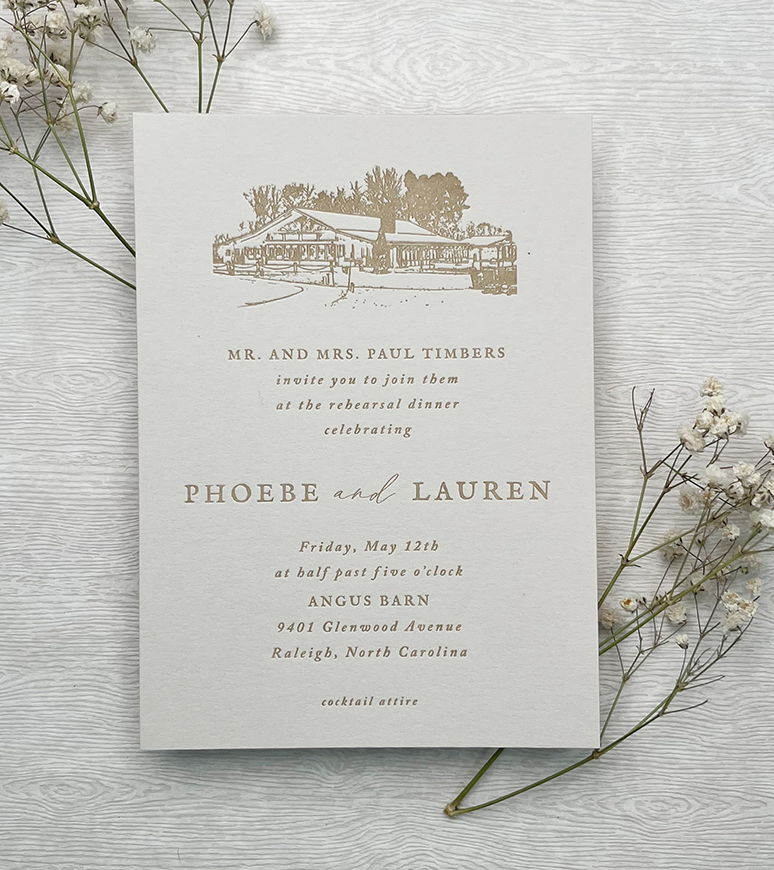

Letterpress

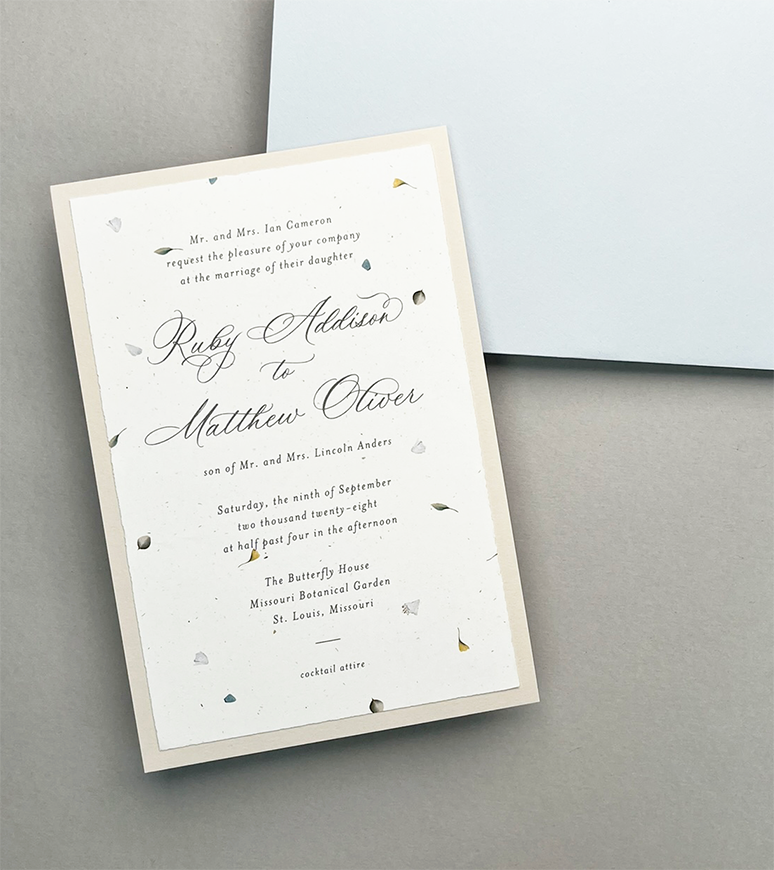

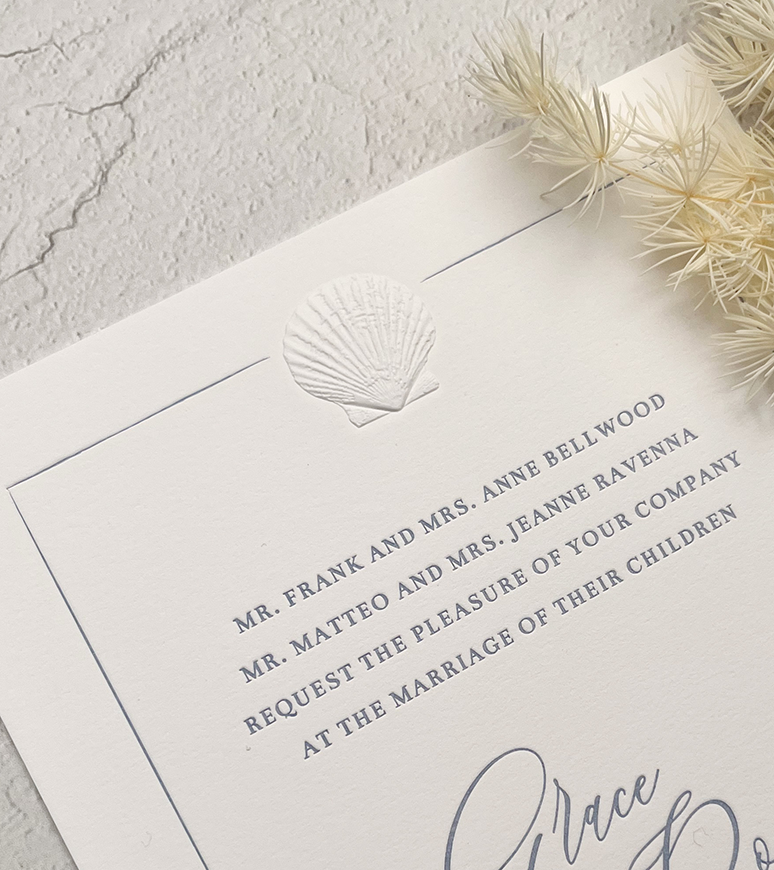

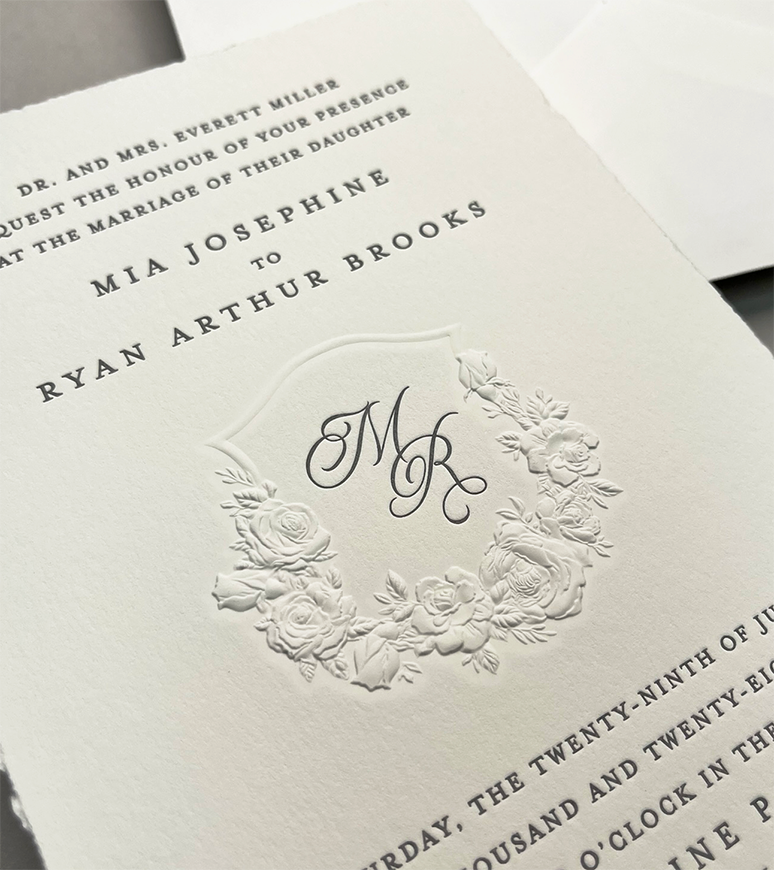

Letterpress, the very first print method, originated in the 15th century. It began with movable engraved wood blocks that were inked and hand-pressed onto paper to create a print.

Today, this artisan print method remains largely the same. Since the invention of flat digital printing, a deep impression into a lofty paper has become a coveted letterpress characteristic. Now, this impression is typically created using plates in place of engraved wood blocks. Although presses have been adapted with safety mechanisms, there is still nothing computerized about this print method! Skilled operators diligently tend to the presses–applying one ink color at a time, aligning the plate, feeding the paper, gauging the pressure and making adjustments for consistency throughout each and every print job. The result is a beautiful design exquisitely pressed into a canvas: a printed work of art!

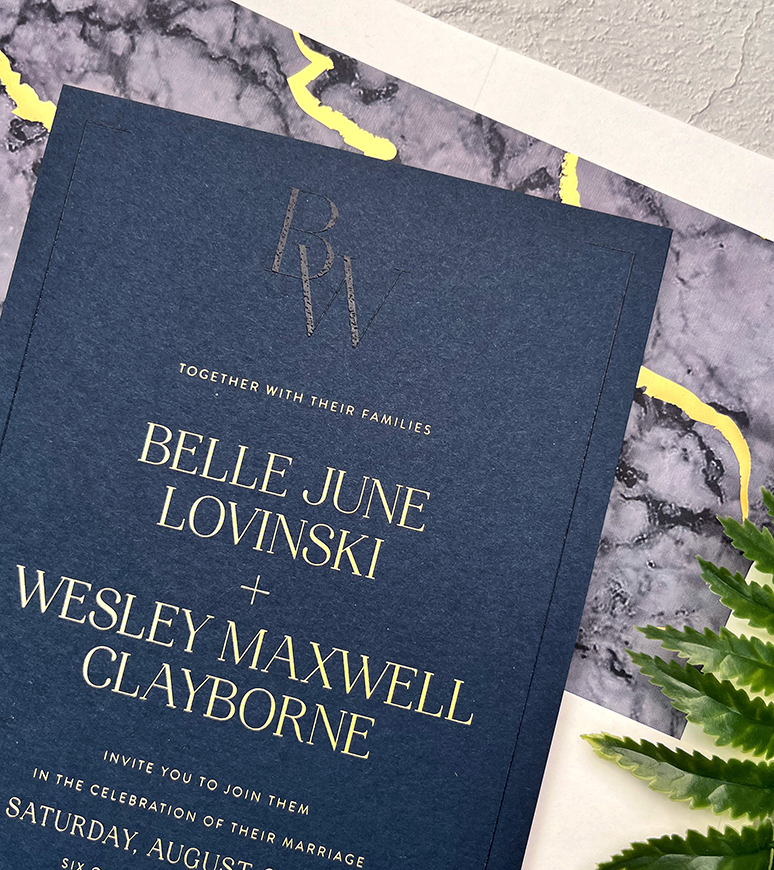

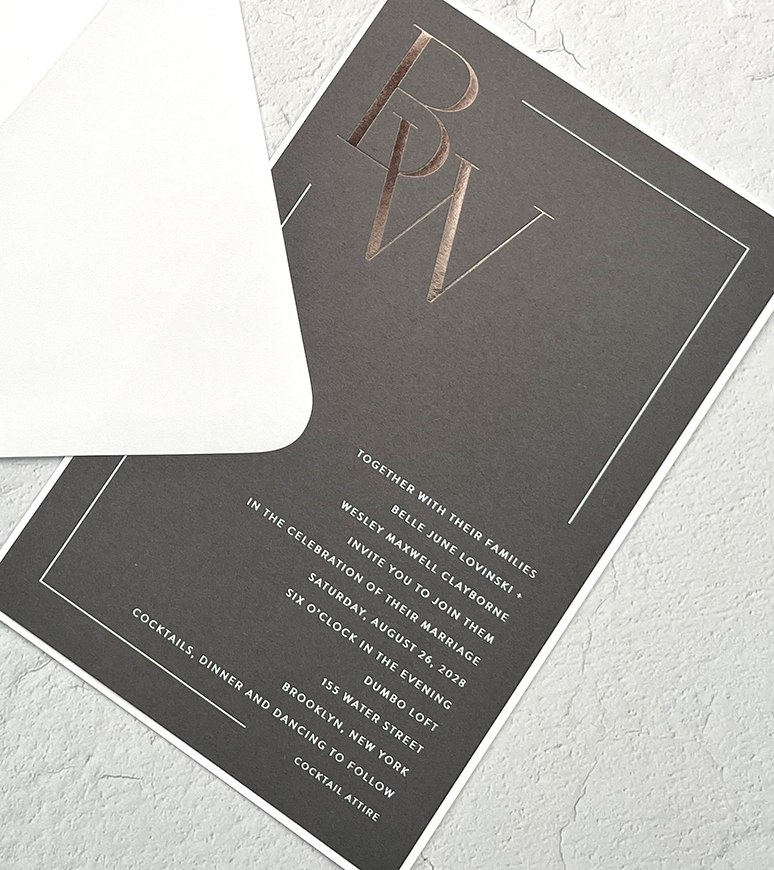

Foil

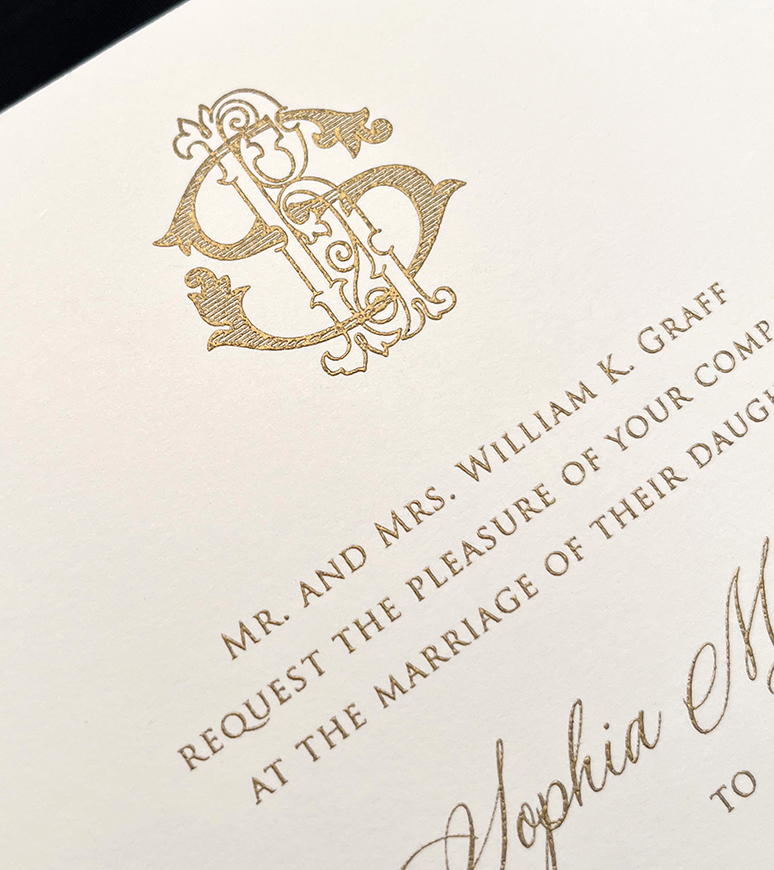

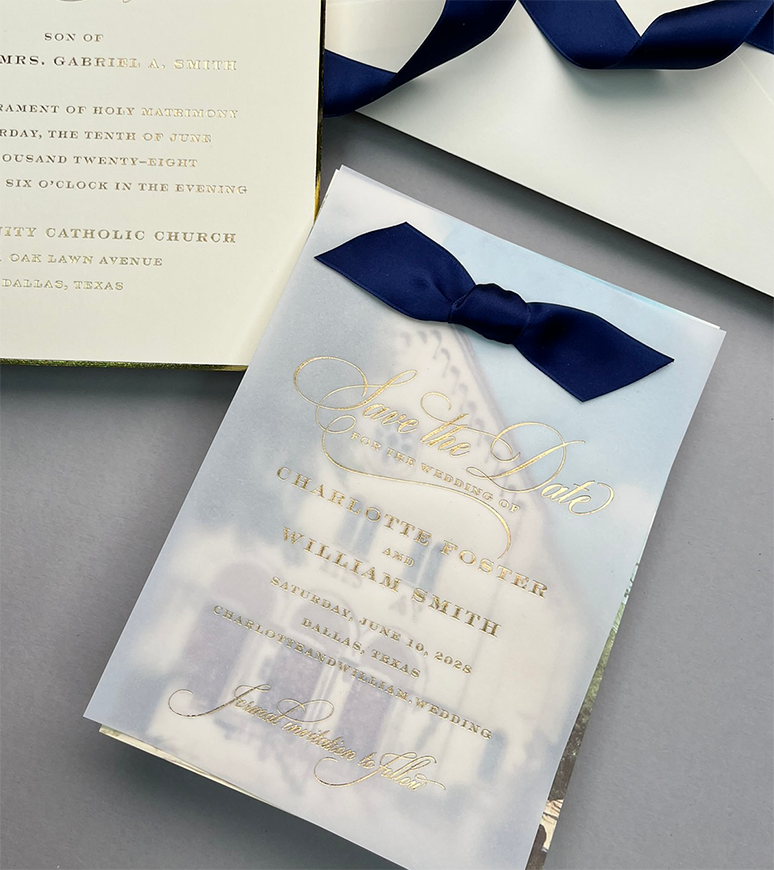

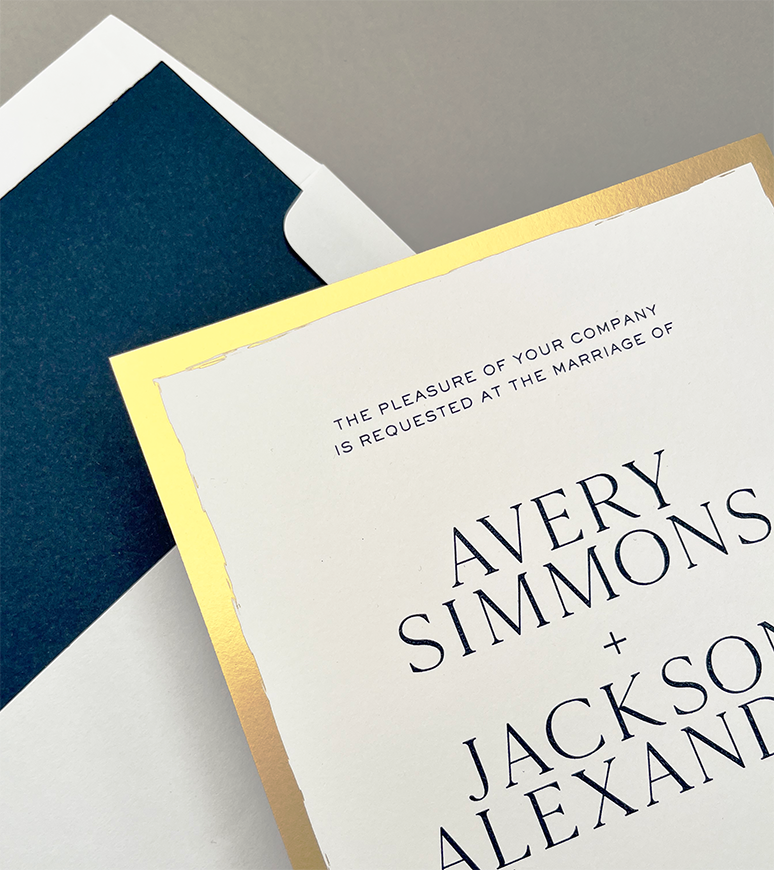

Foil stamping is a specialty printing process with a rich history in adorning precious literary titles with glistening metallic embellishments.

Today, this artisan print method continues to thrive because of its unique finish−opaque, shiny and decadent! Like letterpress, there is nothing computerized about this plate based print method. Foil stamping uses heat, pressure, thin films of foil, and metal dies. Skilled operators heat a plate then use mechanical pressure to imprint and seal a thin film of foil onto the paper. Foil is applied one color at a time and requires constant attention to alignment, paper feeding, and temperature. The temperature is adjusted to best suit the artwork to assure consistent foil coverage throughout each and every print job.

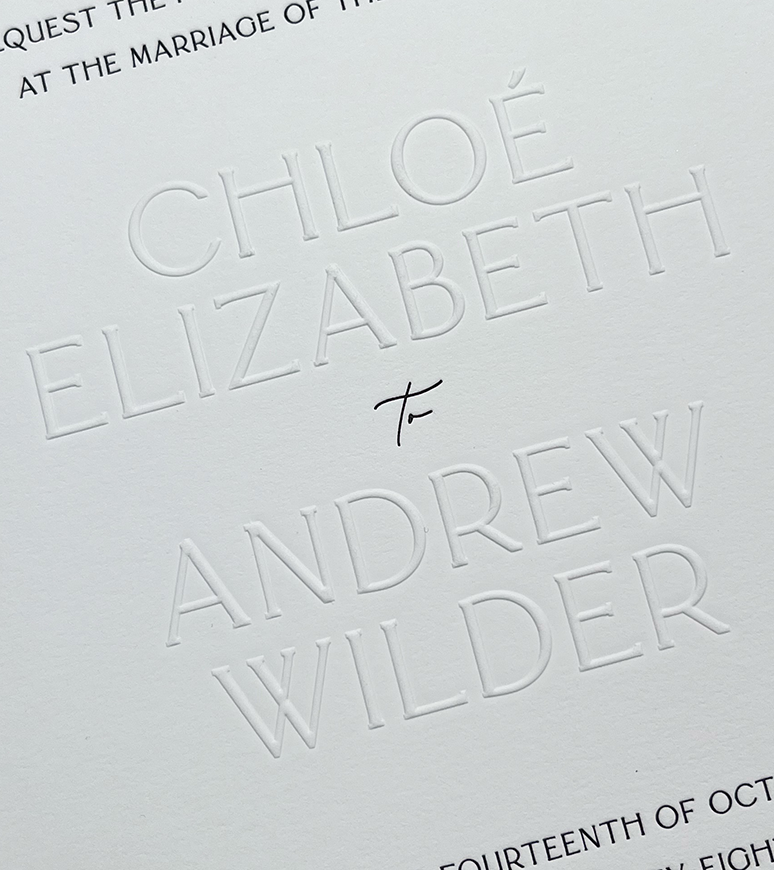

Embossing

Embossing is a technique that creates a raised, three-dimensional design on paper or other materials using a die and counter die to achieve the effect. The paper gets “sandwiched” between the die and counter die which transfers the design to the paper.

Single level Raised Round embossing is recommended for embossed typesetting, for example, names or monogram letters. The amount of “raise” corresponds to the thickness of the line weight. We recommend using thicker line weight fonts for the best effect.

Multilevel Sculpted embossing is recommended for artwork to capture more of the details. These die sets are often more expensive because they require hand sculpting the die to get the varying levels of curves, angles and depths.